Innovatek is a young establishment founded by engineers experienced for several decades in water and wastewater treatment business.

We design and manufacture various components, equipment, pipelines and steel structures based on original ideas developed within the company.

PRODUCTS

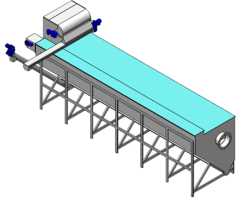

All treatment processes need reliable screening solutions as first step. Non-biodegradable solids must be removed from the flow in order to protect subsequent process equipment against any damages. Otherwise, these damages can cause loss of efficiency for overall treatment process. It is critically important to have a properly designed and sized screening system to ensure the process efficiency and extend the lifetime of the treatment plant.

Grit in wastewater flow causes reduced treatment efficiency and increased maintenance costs. Grit and mineral material content in wastewater flow are very variable and can be contaminated with organic particles or other foreign matter similar to domestic waste. It is necessary to separate the grit and other mineral materials which are conveyed with the wastewater flow to achieve reliable operation conditions. The mineral matter should be removed but the organic matter therein should remain in the wastewater as much as possible.

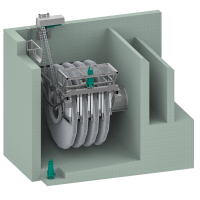

Equipment requiring smallest possible volume is a never-ending challenge. Since reinforced concrete structures require more space and are costly, there is an increasing demand for combining steps of treatment processes and designing compact treatment units, especially for the small to medium sized wastewater treatment plants.

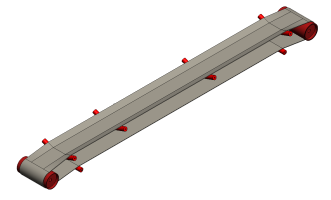

Material handling can place a lot of pressure on conveying equipment, thus must be selected carefully and precisely. Conveyors are used in thousands of industrial applications for conveying and elevating variety of bulk materials. It is important to select correct type and size of conveying equipment to handle the transported material in a correct way.

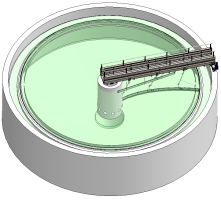

Clarification is an essential step in water and wastewater treatment processes. The aim of the clarification is to remove suspended solids by gravity settling and providing a clarified effluent. Determining the appropriate clarification technology and selecting the proper equipment to fit this technology is highly important to obtain high-efficient results. Selected equipment have an important duty to remove the sediment and floating matter which accumulate as a result of solids separation.

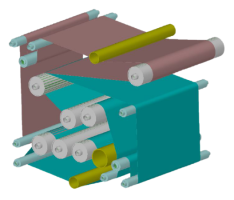

The main waste generated in a treatment plant is the sludge that is removed from mechanical, biological and chemical wastewater treatment processed. The amount of sludge depends on the type of treatment. Reducing the water content within the sludge is very important as it determines the sludge volume and therefore feasibility and costs of transportation and disposal.

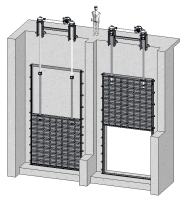

Reliability is a must for flow control equipment, cannot be a compromise. Motivated with high quality demands of our customers, we innovate and improve flow control equipment at the highest level of expertise, design and manufacture with the utmost care.

Innovative products such as cloth filters and compact disc filters stand out with their high efficiency, low energy consumption, and compact design. These systems deliver superior performance across a wide range of applications from industrial facilities to municipal treatment plants enhancing water quality while reducing operational costs.