Products

Search

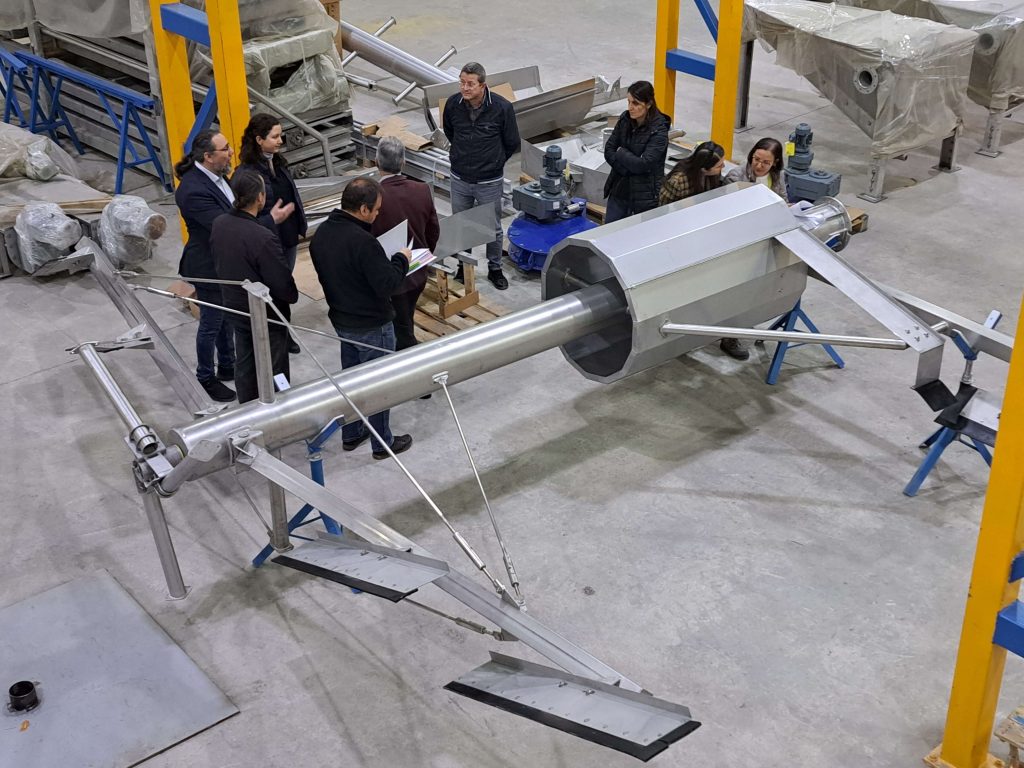

KLARo.PLuS (KLR+) Central Driven Scrapers are especially developed for circular or square tanks. As the flow is very slow the solids settle by gravity. In case of thickening process; the sludge is stirred slowly by means of the vertically mounted members named as picket fence. The sludge in the bottom area, which has the highest thickness concentration, is conveyed by the echelon‐type scraper blade assembly into the sludge hopper, from where it is drawn off by hydrostatic pressure or respectively pumped off to further treatment facilities. Depending on the mode of operation, the supernatant is drawn, continuously or discontinuously, from the surface via overflow weir on an outlet channel or via height adjustable or floating supernatant outlets.

The equipment comes with a robust central drive unit which comprises an electric motor and a multistage reduction unit. The mechanism is often assembled on a fixed bridge which is being supported by peripheral walls. Also central pier supported assembly is used as an alternative design in which the scraper is carried by a central column.