Products

Search

– INNOVATION IN TERTIARY WATER TREATMENT –

- The filter cloth is available with mesh opening sizes ranging from 5µm equivalent.

- 100% submerged design in combination with increased filtration surface for higher capacities.

- TSS removal, BOD and COD partial reduction, phosphorus reduction down to 0.1 mg/l.

- The non metalic chain does not need any lubrication.

- The design of the shaft and its mounting provides an extraordinary long sealing life span.

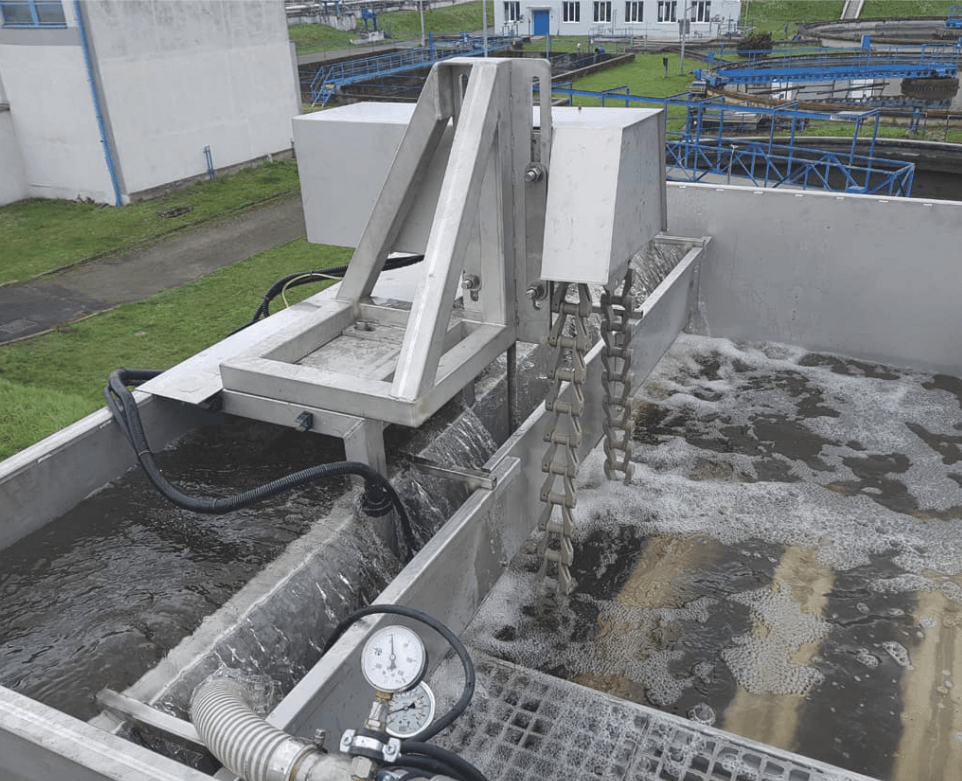

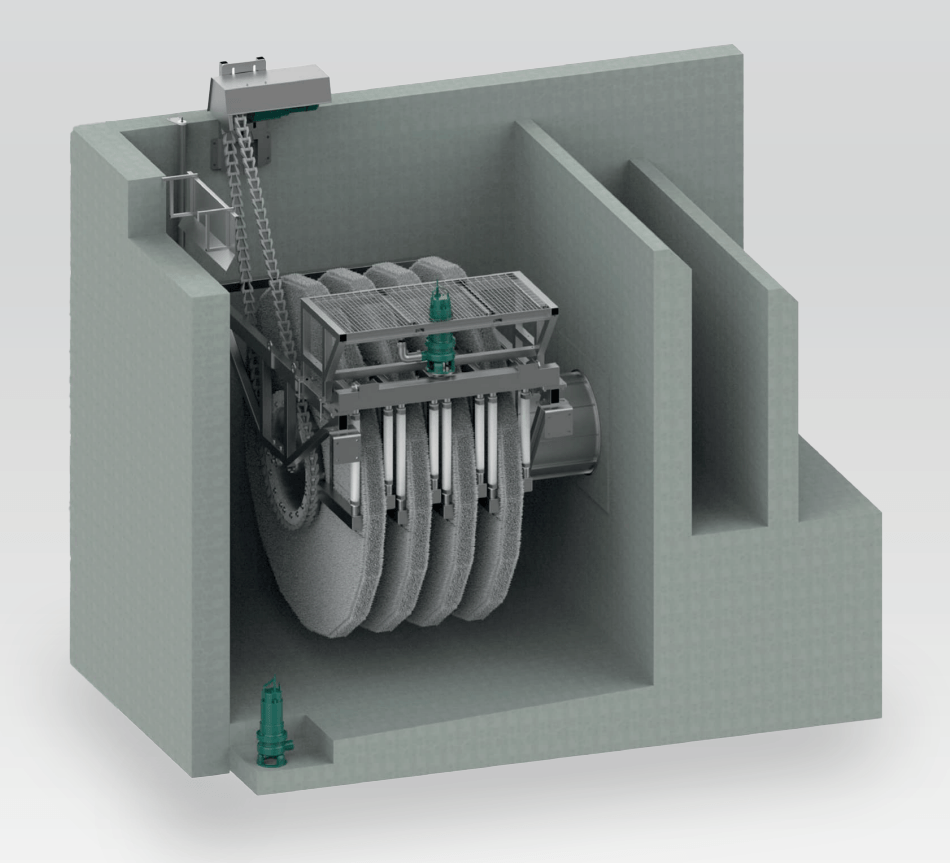

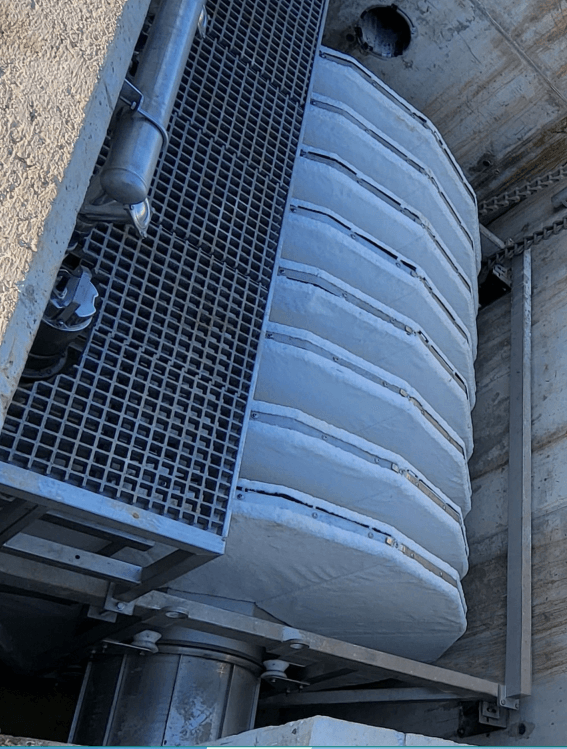

The untreated water including its impurities flows into the filter pit. There is a filter including the filtration cloth on the segments, which forms individual discs. The entire system is 100% submerged. Water passes through the filtration cloth inside the hollow shaft retaining the impurities on its surface.

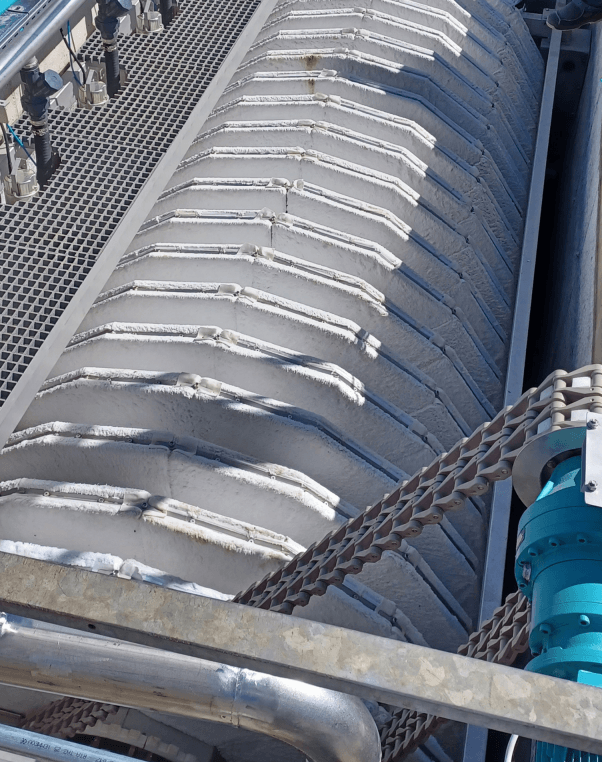

As the impurities get caught on the filter cloth, the flow decreases and the water level in the filter pit rises gradually. When the water level probe is activated, the filter discs start to rotate and initiate the cleaning process. This process involves slow rotation and suction of the impurities.

As the water level decreases to the pre-set minimum water level and the backwash cycle ends, the unit stops rotating and filtration returns to its maximum capacity at minimum level. The filtration cycle repeats. Filtration goes on continually without interruption.

For greater variability and adaptation to the spatial and capacity needs of each project, different size series of pile cloth filters have been developed;

A smaller compact device with a diameter of 1m, medium sized device with a diameter of 2.2 m, and the largest sized device with a diameter of 3m providing the biggest filtration area and capacity.

FC2 / FCi (Intensified Compact Version)

- Disc Diameter: 2.2m

- Up to 32 discs

- Ideal for medium and large applications

We can also supply two special & tailor-made versions with 1 m diameter and even 3 m diameter discs.

They are only made-to-order versions to support our partners with customized versions to suite projects‘ needs.